The world is changing with an unstoppably evolving massive global mindset shift. Sustainability is becoming not a beneficial option but a must, not only in the automotive or plastic but also in the fashion business. While demand for sustainable brands grows, this article will dive into polymers and will help show the way to sustainable fashion.

Finding better solutions: Polymers from renewable resources

As we know, oil and other hydrocarbon compounds, such as natural gas, are rich in raw chemical materials. Still, at the same time, these resources are limited and often require a lot of energy to process into useful products. These products are often non-biodegradable and generate a lot of waste. The solution to recycle these products or use them for a second or third time does not solve the problem comprehensively. This is mainly because recycling costs more than making a new product, and the energy consumption spent melting polymers during the recycling process creates additional emissions. That is why scientists are on a mission to find a better solution. And significant progress has been made in finding alternatives to generate renewable energy sources, for instance, from the sun and the wind. Still, is it possible to use renewables for polymers as well?

Many plastics and polymers until now were made from fossil fuel, mainly because fossil fuel is a rich source of hydrocarbons. Therefore, until now, the understanding about plastics and polymers has been primarily that fossil fuel is considered a primary source. However, the polymer can also be made using the synthesis of new chemical compounds derived from plant sources. To move to more sustainable, renewable, and environmentally friendly raw chemical materials, researchers have been looking for opportunities to produce high-quality polymers from renewable raw materials with little or no environmental impact.

Vegetable oils (plant triglycerides) are one of our planet’s most abundant renewable resources. Since ancient times, people understood the importance of vegetable oils that are still used even today, for example: in the production of ink, varnish, soap, biofuels, and the development of macromolecular materials.

All plastics are polymers that are made from repeating elements called monomers. Hundreds or thousands of monomers in a polymer combine to form long chains. Depending on the density and length of these chains, the final plastic may have different properties. For example, due to the high density of chains, polyethylene is very light and strong, suitable for bottles, and low-density chains are suitable for flexible products such as bags.

Monomers derived from vegetable oils

Monomers can be made from vegetable oils by using only one step of the synthesis process. Vegetable oils are a great starting material because many of them are non-toxic, naturally biodegradable, easy, and inexpensive to extract. Chemically, the oil consists of triglycerides, fatty acids, and glycerol esters. There are plenty of ways to extract vegetable oils from seeds, such as rapeseed (canola) oil. Precisely these oils can be successfully used as raw material for the synthesis of monomers.

Oils are converted to monomers, which are used to make polymers and polymeric materials. Although vegetable oil-based monomers can be used directly to make existing monomer-based materials, they are also excellent in the development of biological polymer structures. The developed vegetable oil monomers have a dual functionality that causes polymer chains to grow in free radical polymerization and double bonds in fatty acid chains that are retained during polymerization that can be used in post-polymerization cross-reactions.

Polymers for all shapes, colors and surfaces

There is already a stable industrial process able to produce enough polyurethane polymers derived from vegetable oils with long aliphatic (hydrocarbon) chains with different amounts of double bonds, which gives the material flexibility. The advantage of emulsion polymers derived from vegetable oil is that they can form hydrophobic intermediates when the required shape and color are obtained, making vegetable oil-based monomers ideal for the synthesis of polymeric materials. The new synthetic method is important not only because it opens the possibility of developing biological polymers but also because it is done quite simply and uses the development of renewable ecological raw materials.

The new synthetic method allows for a relatively easy formation of biological polymers. Monomers can also be blended with intermediate petroleum products or biological compounds to form mixed polymer-copolymers that allow the water resistance and plasticity of vegetable oil-based polymers to be combined with the desired properties of other families of polymers. This means that the biodegradability and elasticity of the final copolymer can be precisely tailored to the specific application to produce a sustainable polymeric material.

The most important property of vegetable oil-based monomers is that they can form emulsion polymers, otherwise known as latexes. An emulsion is formed when the compound is insoluble in the solvent and remains in the form of dispersed droplets. One well-known daily example of an emulsion is milk, a dispersion of oil droplets in water. Emulsion polymerization is a very important process because a ready-to-use polymer is obtained, and this type of polymerization is easily carried out in water. This means that emulsion polymers can be formed based on water.

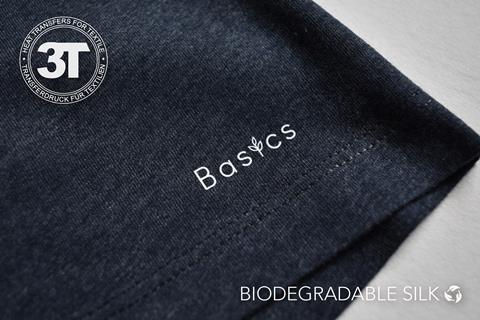

Such emulsions can be colored using water-based pigments. After drying, the copolymer leaves the final polymer forming a combination of shape, color, and a certain surface, which can then be prepared as an element of textile accessories. Using vegetable oil-based polymers in textile accessories further elevates the sustainability cartel. In this way, not only do the chemicals not pollute, but they are also not harmful to health. Additionally, the use of the planet’s non-renewable resources is also minimized.

The future of textile accessories: Renewable energy and plant-based polymers

By using renewables, CO2 emissions are reduced, and factories are less toxic and safer. This new development of textile accessories has been carried out by a technically mature new generation of polymers, which, after long studies, has led to the development of polyurethanes using renewable energy sources that concurrently guarantee the same properties as fossil fuels.

For more information:

Check our website: www.3t.lt or contact us directly for more details at info@3t.lt.

Our Social Media: Facebook and LinkedIn

Visit us at ISPO Munich 2022 (Nov. 28-30) in Hall C2, Booth 323

Literature:

Alessandro Gandini, Talita M. Lacerda. 2019. Polymers from Plant Oils. 2nd Edition.

Andriy Voronov 2021. High-performing monomers and polymers from plant oils.

Hiroshi Uyama. 2018. Functional polymers from renewable plant oils. J 50, 1003–1011 (2018).

Kohut, A., et al. 2020. Non-Conventional Features of Plant Oil-Based Acrylic Monomers in Emulsion Polymerization. Molecules, 25, 2990.

Lucas Montero de Espinosa, Michael A.R. Meier. 2010. Plant oils: The perfect renewable resource for polymer science?!